In today’s rapidly evolving global market, businesses are constantly seeking ways to optimize their supply chains to stay competitive and meet growing consumer demands. One key factor that is often overlooked in this optimization process is industrial packaging. Industrial packaging bags, which are used in a variety of industries from manufacturing to food production, have become a critical component in improving supply chain efficiency.

In this blog post, we will explore how industrial packaging bags are redefining the supply chain landscape and how companies are leveraging them to enhance productivity, reduce costs, and improve overall performance.

The Growing Importance of Packaging in Supply Chain Management

In the past, packaging was primarily seen as a means of protecting goods during transit. However, as supply chains become more complex and customer expectations rise, packaging has evolved to serve a much broader purpose. Today, industrial packaging bags are being designed to not only safeguard products but also streamline the movement of goods through the supply chain, improving efficiency at every stage.

Packaging plays a vital role in managing logistics, inventory, and handling processes within the supply chain. When optimized, packaging can drastically reduce costs, minimize product damage, and accelerate the flow of goods from one point to another. Industrial packaging bags are particularly beneficial in this respect due to their versatility, cost-effectiveness, and ease of use.

The Role of Industrial Packaging Bags in Supply Chain Efficiency

Industrial packaging bags play a pivotal role in optimizing supply chain processes by improving logistics, reducing transportation costs, and enhancing storage efficiency. These bags provide durable and cost-effective solutions that streamline the movement of goods while maintaining product integrity throughout the supply chain.

1. Streamlined Logistics and Storage

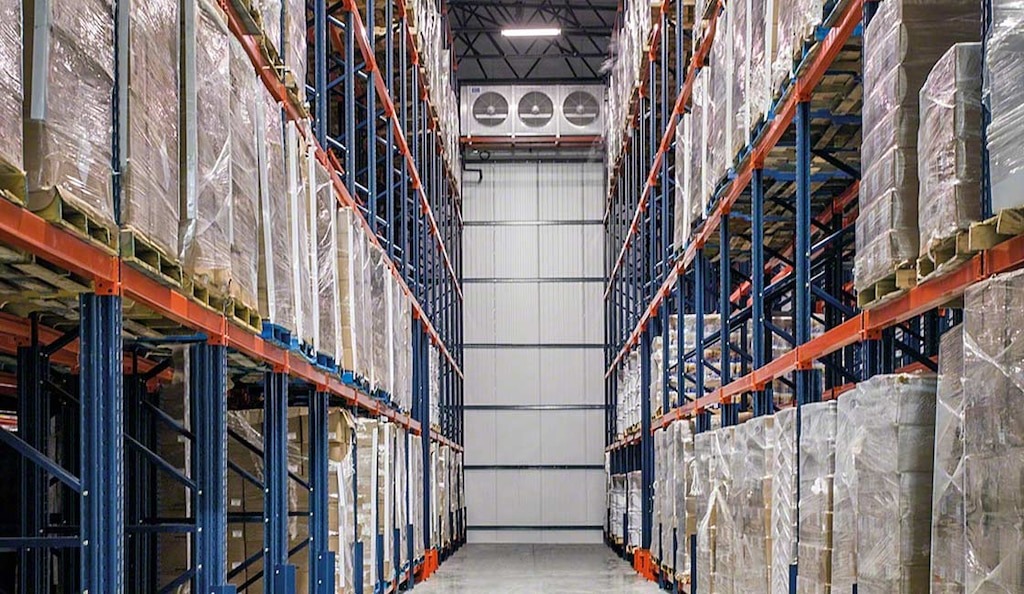

One of the primary ways industrial packaging bags contribute to supply chain efficiency is by improving logistics and storage management. These bags, whether made from woven polypropylene, BOPP (biaxially oriented polypropylene), or other durable materials, are lightweight yet strong enough to carry large quantities of goods. This characteristic makes them easier to store, transport, and handle in warehouses.

The ability to stack industrial packaging bags neatly allows for more efficient use of space in storage facilities. Additionally, these bags can be designed to fit specific sizes, reducing wasted space in shipping containers, which leads to cost savings on transportation. With the global shift toward Just-In-Time (JIT) manufacturing and the need for rapid distribution, the ability to pack products efficiently has never been more important.

2. Cost-Effective Solutions for Bulk Shipping

For industries that ship large quantities of goods, industrial packaging bags are an ideal solution. These bags are particularly cost-effective for bulk shipping, as they can accommodate large volumes of products without the need for multiple individual packages. This not only reduces the cost of materials but also lowers the overall shipping costs.

By consolidating goods into large bags, companies can minimize the amount of packaging material used and reduce the environmental impact of excessive packaging. Moreover, the uniformity of industrial packaging bags simplifies the handling process, as they can be loaded and unloaded with ease using standard equipment, such as forklifts and conveyor belts. This further accelerates the movement of goods and reduces labor costs.

3. Improved Product Protection During Transit

Product damage is a common challenge in logistics, especially when items are being transported over long distances. Industrial packaging bags are designed to protect products from a wide range of potential hazards, including moisture, dust, UV rays, and physical damage. For instance, bags that are made from UV-resistant materials can protect products like chemicals, pharmaceuticals, and agricultural goods from degradation caused by prolonged exposure to sunlight.

In addition, many industrial packaging bags come with features such as double-sealing, airtight closures, and waterproof linings, all of which enhance product protection during transit. By ensuring that products arrive at their destination in optimal condition, businesses can reduce the likelihood of returns, damage claims, and customer dissatisfaction—leading to a smoother supply chain process.

4. Simplifying Inventory Management

Efficient inventory management is essential to maintaining a smooth and cost-effective supply chain. Industrial packaging bags simplify inventory management by enabling easy categorization, labeling, and tracking of goods. With clear, consistent labeling and barcodes, it becomes easier to monitor the movement of goods in real-time, helping businesses reduce the risk of stockouts or overstocking.

Moreover, the lightweight and space-efficient nature of industrial packaging bags allows for higher storage capacity within warehouses. With more efficient use of space, businesses can store larger quantities of inventory in the same area, which increases inventory turnover and helps to keep costs under control.

5. Enhanced Traceability and Compliance

As businesses become more global, traceability and compliance with international standards have become critical considerations for supply chain management. Industrial packaging bags equipped with RFID (Radio Frequency Identification) tags or QR codes can provide real-time tracking and ensure the transparency of the supply chain.

These technological advancements help businesses track shipments from the moment they leave the warehouse to their arrival at the final destination. In industries such as pharmaceuticals and food production, traceability is essential for meeting regulatory requirements. The ability to trace products at every stage of the supply chain ensures compliance with safety and quality standards while providing critical data for improving operations.

Sustainability and the Future of Industrial Packaging Bags

Sustainability has become a key focus for many industries, and packaging plays a pivotal role in reducing a company’s environmental footprint. Industrial packaging bags are increasingly being manufactured from eco-friendly materials such as biodegradable plastics, recycled fibers, and organic cotton.

By shifting to these sustainable materials, companies can significantly reduce their waste and contribute to global efforts to combat pollution. Additionally, the lightweight nature of industrial packaging bags minimizes fuel consumption during transportation, further enhancing the sustainability of the supply chain.

As the demand for eco-friendly solutions continues to grow, the packaging industry is expected to embrace more innovations in sustainable materials and practices. Companies that adopt these sustainable packaging solutions will not only help protect the environment but also benefit from the growing consumer preference for environmentally responsible products.

Conclusion

Industrial packaging bags are no longer just an afterthought in supply chain management—they are integral to improving efficiency, reducing costs, and ensuring the smooth flow of goods from one point to another. From enhancing storage and logistics to providing better protection during transit, these bags are a game-changer for businesses looking to optimize their supply chains.

As industries continue to embrace new technologies and sustainability practices, industrial packaging bags will undoubtedly play an even more prominent role in shaping the future of supply chain efficiency. By utilizing the benefits of these versatile and cost-effective packaging solutions, businesses can stay competitive, meet customer demands, and reduce their environmental footprint.

In the evolving landscape of global commerce, leveraging the power of industrial packaging bags is a smart, sustainable, and practical solution for redefining supply chain success.